Five Steps to Manage Health and Safety Risks

SiteSafe - October 2017

Under the Health and Safety at Work Act, if you're a person in charge of a business or undertaking (PCBU), you need to protect your workers and anyone else on site by managing risk. Not only is risk management a key part of your legal responsibilities, it can also lead to better productivity, better contractor relations and happier workers.

PCBUs must manage risk:

Section 30 of the Health and Safety at Work Act requires you to eliminate risks, so far as is “reasonably practicable”. To be reasonably practicable simply means to consider the level of risk, what you know about ways of controlling it, and the cost in relation to the level of risk. This does not mean that if the control is too expensive it can be dispensed with. If the risk of death or serious injury exists, the question should be whether or not the job is worth the risk. If you can’t eliminate the risk, then you must minimise it as far as is reasonably practicable.

Which hazards need to have a process for assessing and managing risk?

- All of them - but not all will require a formal process

- If you are just starting out, begin with the major risks that could cause serious injury or death

The 5-Steps to Managing Risk:

#1 Identify hazards

#2 Assess the level of risk for each

#3 Control the risk to reduce the harm and its severity

#4 Reassess the level of risk for each hazard

#5 Review and monitor that controls are working and risks levels are acceptable

Step One: Identify

Walk around your workplace with a worker and identify what could seriously harm the health or safety of workers and others. Remember to think about immediate safety hazards, like falls and gradual health hazards like asbestosis.

Step Two: Assess

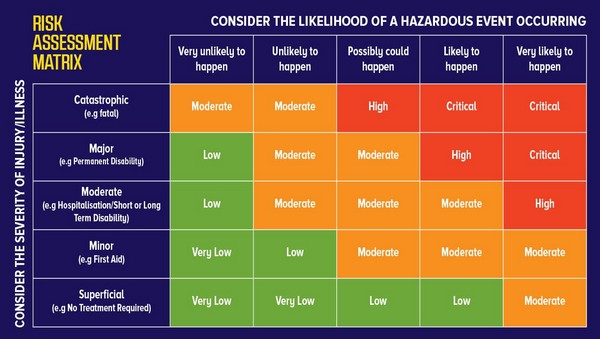

Once you have identified the hazards, assess the level of risk for each. This is a great time to talk to your workers, who are your greatest source of information during the risk assessment process. They know and understand the jobs, how they can suffer potential harm, and the controls that are or aren’t working. Your workers will often have great ideas for improvement, so just ask! To work out the level of risk, determine how likely it is to occur and what might be the possible severity of injuries. Using a risk matrix as a guide can be useful.

Step Three: Control

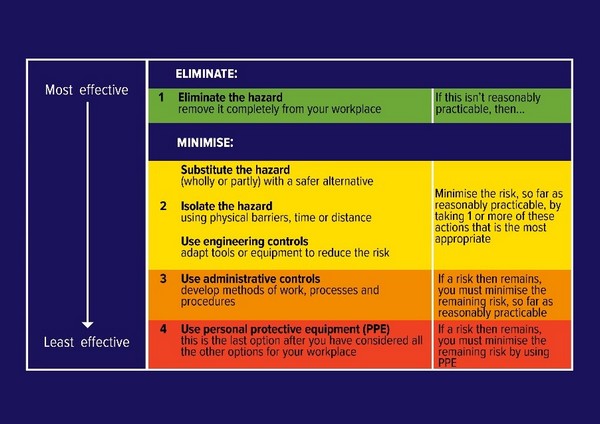

Once you have identified the level of risk, you must do what is reasonable and practical to eliminate it. Where it can’t be eliminated, minimise it by choosing the best controls for the situation. The better the level of control, the lower the level of risk. Common controls can be applied for common risks. Remember to talk to subbies and anyone else on site about risks from your work. If you can’t eliminate a common risk, then apply common control measures, Codes of Practice, guidelines, standard procedures, etc. Use a risk register to record your common hazards and controls. If you can’t eliminate a specified risk and it is: covered by regulations or high-risk, then apply the “hierarchy of controls” and use a Task Analysis or a Safe Work Method Statement.

Controls can be ordered from most effective to least. This is called the “Hierarchy of Controls”. The better the controls used, the lower the level of risk. The most effective control is to eliminate, the least is to just use PPE. Substitute, isolate and engineer are classed as being as equally effective. You will often need to use multiple controls on a single risk.

Step Four: Reassess

After putting in place controls, go back and reassess the level of risk. You may not always get your controls right the first time. If the new level of risk is still too high, go back and reassess it with different controls.

Step Five: Review and Monitor

You’ll need to review your controls regularly to:

- Ensure your planned controls are being used

- Check that controls are effective

- Ensure your risk level estimate is correct

- Check in with workers if controls are convenient and effective

- Monitor exposure to health

- Identify new or different work activities and risks

- Consider if stronger controls are now possible

Want more help? Site Safe offers a free Risk Management guide designed specifically for SMEs, as well as a new Risk Management course. To enrol, or to download the guide, go to www.sitesafe.org.nz.

Site Safe is a not-for-profit, membership-based organisation that promotes, inspires and supports a culture of health and safety in New Zealand construction.